-

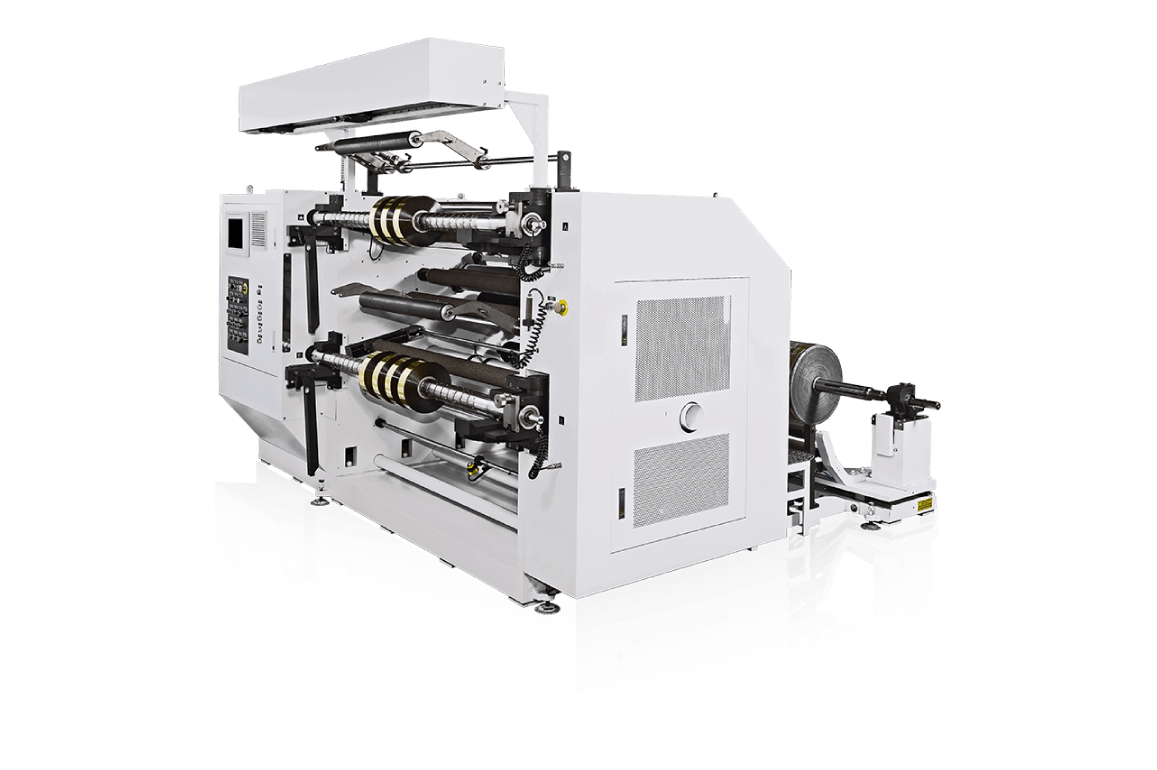

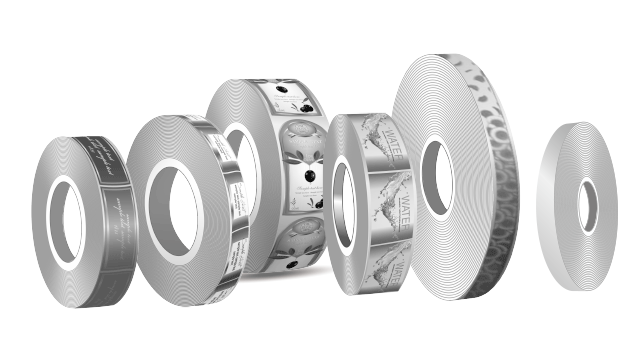

The Kimera Series Laminated Film Slitting Machine is engineered to meet the diverse needs of industries working with laminated films, and it also functions as an effective meltblown nonwoven fabric slitting machine. Designed for precision, speed, and flexibility, Engineered for precision, speed, and flexibility, it's ideal for slitting and rewinding various materials while maintaining operational efficiency.

-

Efficient Setup and Material Handling

-

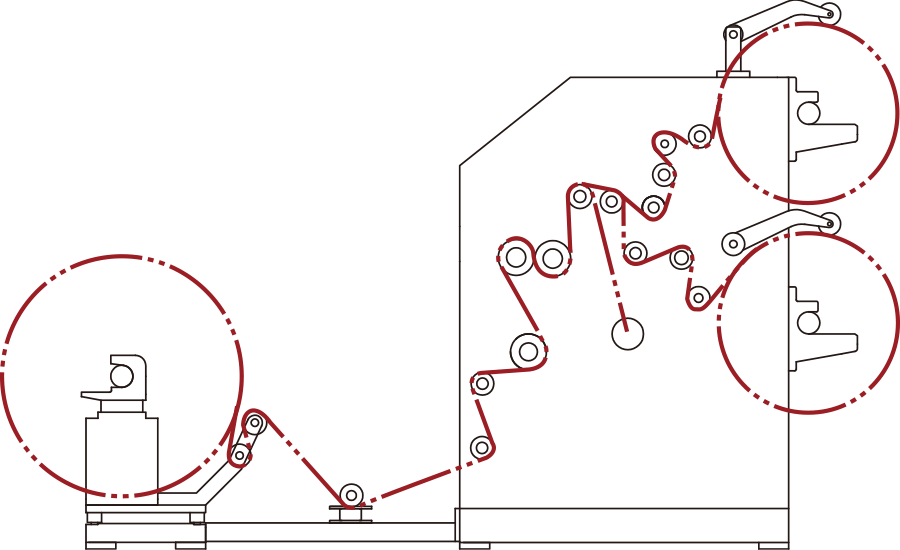

Quick Roll Changes

A 3" swing-out/lift-up air shaft enables rapid roll changes, minimizing downtime.

-

Real-Time Material Alignment

A line and edge position control (LPC) system with a CCD camera ensures accurate material alignment for precise slitting.

-

Laser Core Positioning (Optional)

For added precision, a laser device can be added to guarantee accurate core positioning during roll setup.

Flexible and Precise Cutting Capabilities

-

Razor Cutter

The razor cutter, combined with a grooved roller, ensures clean, precise cuts for thin, fragile materials, including meltblown nonwoven fabric commonly used in medical and biotech applications, such as those found in face masks.

-

Shear Cutter (Optional)

For thicker, multi-layered materials, an optional shear cutter can be added.

Seamless Rewinding and Roll Management

-

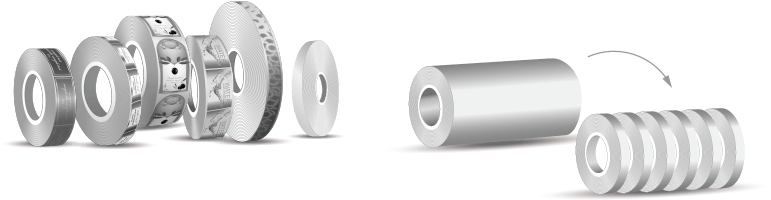

Friction Shaft

A pneumatic-controlled friction shaft with a lift-up design allows quick unloading and easy roll changes, supported by a reverse-run mode.

-

Automatic Diameter Adjustment

The tracking roller adjusts to changing roll diameters to maintain tension.

-

Lay-on Rollers for Consistent Pressure

Lay-on rollers apply even pressure to prevent roll shifting.

-

Unloading Device (Optional)

To streamline the process, an unloading device can be added to simplify the handling and removal of completed rolls.

Advanced Tension and Control Systems

-

Automatic Tension Control

The machine’s automatic tension control system ensures steady tension across different material types, including meltblown nonwoven fabrics.

-

Touchscreen Interface for Easy Operation

Operators can easily manage key parameters – such as speed, total length, and rewinding length – through an intuitive touchscreen control panel. The system can store up to 1,000 work parameters, allowing quick access to past setups.

High-Speed Production with Static Control

-

High-Speed Performance

This machine achieves up to 300 meters per minute for efficient production.

-

Static Eliminating Brushes

Prevent static buildup to ensure smooth, uninterrupted operation, especially important when working with lightweight materials like meltblown nonwoven fabrics.

With its high speed, precision, and flexibility, the Kimera Series Laminated Film Slitting Machine, also a capable meltblown nonwoven fabric slitting machine, is the ideal solution for efficient material processing. Interested in learning more? Contact us today to see how the Kimera Series can enhance your production line. -

| Model No. | SLF-NT130MU |

|---|---|

| Applicable Material | LLDPE 40-150μ, PE;OPP;CPP;PVC;PET 30-150μ, PET 12-150μ, BOPP 25-150 μ, Laminated films 40-150μ; Meltblown Nonwoven Fabric |

| Min. & Max. parent web width | 650~1300 mm |

| Max. parent web diameter | 800 mm |

| Unwind / rewind core I.D. | 3" or 6" |

| Max. rewind diameter | 600mm |

| Min. & Max. slit width | 50~650mm (Depends on various materials' conditions) |

| Max. machine speed | 300 M/min. |

| machine color | White |

Gravure and flexographic printing

Digital printing

Medical

Metalized

Hot stamping