-

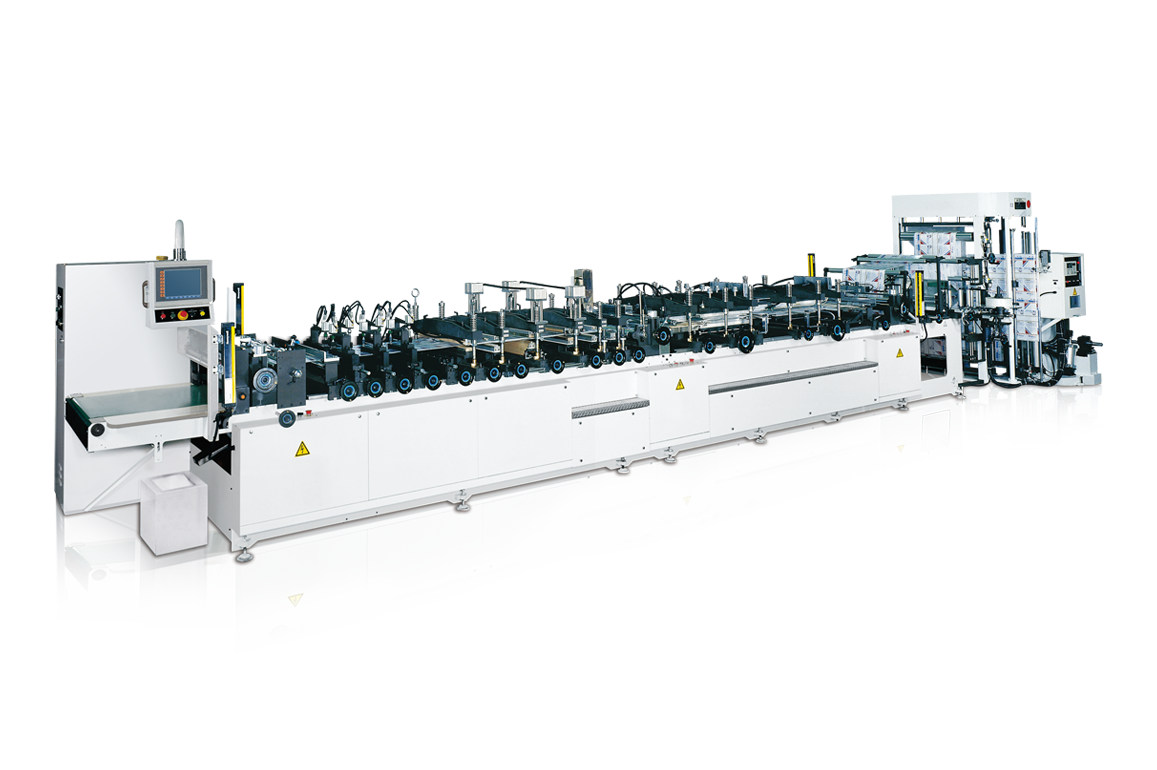

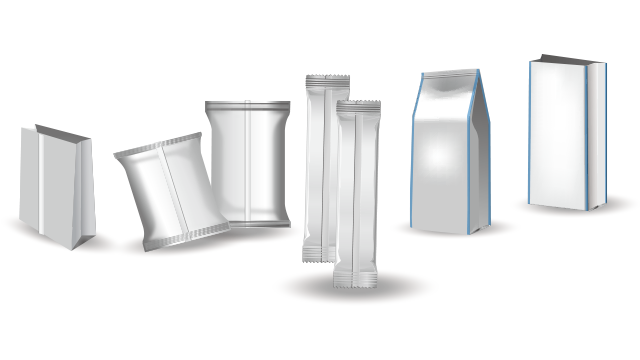

Dah Bah's Stand-Up and Zipper Bag Making Machine is a versatile solution for efficient packaging, designed to produce a variety of bag styles, including coffee bags, snack pouches, and powder packets. This advanced coffee bag machine offers innovative features and user-friendly controls to enhance production capabilities while ensuring high-quality results.

Optimized Material Feeding and Handling

-

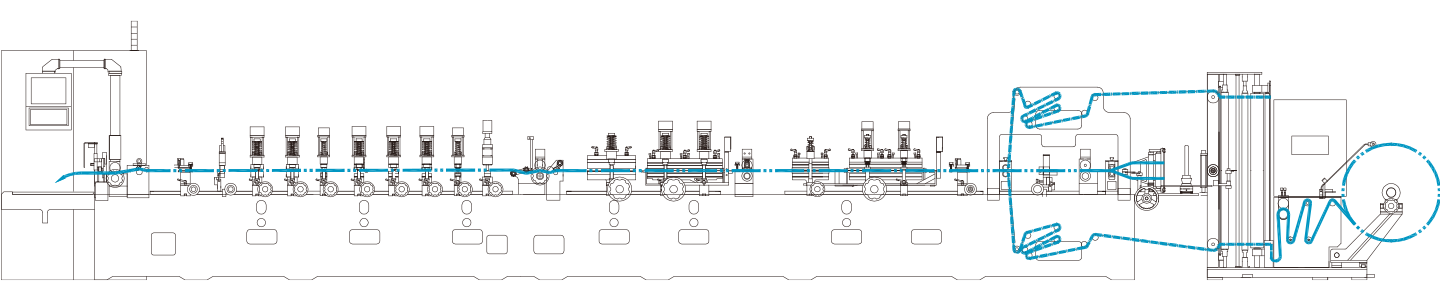

Dual Unwinding Stands (Optional)

Two unwind stands provide continuous feeding of both the main film and bottom strip, ensuring smooth operation.

-

Bottom Strip Unwind Stand

Dedicated stand for bottom strip materials, maintaining accurate alignment during pouch production.

-

Feeding Servo Motors

Dual servo motors enhance production speed and ensure precise bag lengths for seamless material handling.

-

E+L Position Tracker and Alignment System

Precise synchronization between top and bottom film layers minimizes waste and ensures optimal feeding.

Precision Sealing and Cutting

-

AC Servo Motor-Driven Sealing

Accurate sealing times for consistent heat seals at high speeds, ensuring high-quality results.

-

Advanced Tension Control

Equipped with a reel diameter calculation-based automatic tension controller, the machine ensures consistent and stable material tension throughout the production process, minimizing material waste and enhancing cutting precision.

-

Ultrasonic Welding for Zippers

Flattens and secures zipper seals, improving bag aesthetics and preventing leakage.

Smart Control and User-Friendly Design

-

Touch Screen Control Panel

Intuitive interface for easy adjustment of settings, with built-in data storage for quick retrieval of job parameters.

-

Print Mark Alignment

Ensures precise sealing and cutting according to pre-printed marks on the film, optimizing bag presentation.

The Stand-Up and Zipper Bag Making Machine is a valuable asset for packaging lines, offering unparalleled versatility and efficiency in producing a wide range of bags, including high-quality coffee bags. This coffee bag machine’s features are designed for precision, ease of use, and safety, making it an ideal choice for diverse packaging needs. Contact us today to learn more about how this advanced machine can enhance your production capabilities.

For those seeking a complete packaging solution, we offer a range of sealing machines that complement the bags produced by this machine.

-

| Model No. | ABM-64SPZ | |

|---|---|---|

| Max. Parent Web Width | 600 ~ 1200 mm | |

| Max. Parent Web Diameter | 800 mm | |

| Max. Bag Width | 600 mm | |

| Max. Machine Speed | 180 Cuts / min. | |

| Bottom Web Width | 60 ~ 120 mm | |

| Max. Bottom Web Diameter | 420 mm | |

|

Installation Information (For Standard Specification) |

Net Weight | 4700 kg |

| Area Required | L 12141 x W 5229 x H 1795 (mm) | |

| Power | 380V / 31KW / 65A | |

| Water | 15 - 20 ℃ | |

| Air | 6 kg / cm3 | |

| Various Punching Tools | |||

|---|---|---|---|

| Euro-slot | Curve-slot | Butterfly | Slot |

|

|

|

|

| Hexagonal | Round | Star | Kidney |

|

|

|

|

Food

Steam

Frozen

Rice

Clothes

Mask

Liquid

Antistatic

Digital Printing